Services

What We Offer

OUR SERVICES

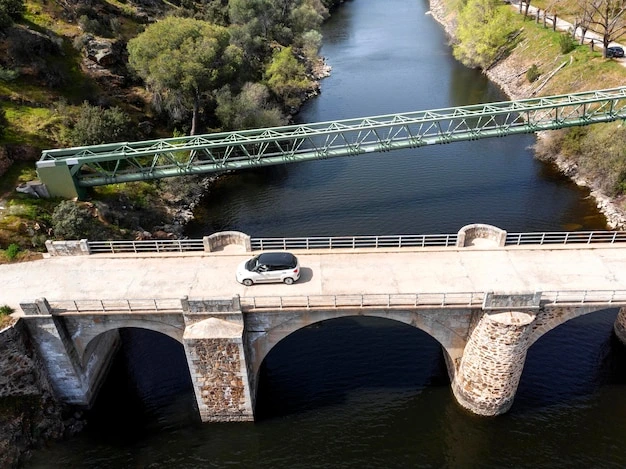

Mobile Bridge Inspection Unit (MBIU)

Rebound Hammer Test

The Rebound Hammer Test, also known as the Schmidt Hammer Test, is a non-destructive method used to evaluate the surface hardness of concrete. This test involves striking the concrete surface with a spring-loaded hammer and measuring the rebound distance of the hammer. Widely used for quick assessments, the Rebound Hammer Test helps identify areas of poor quality or deteriorated concrete. It is an essential tool for engineers and inspectors to assess the uniformity of concrete, plan maintenance activities, and ensure the overall integrity and safety of concrete structures.

Ultrasonic Pulse Velocity Test

The Ultrasonic Pulse Velocity (UPV) Test is a non-destructive technique used to assess the quality and integrity of concrete structures. By measuring the travel time of ultrasonic pulses through the concrete, this test evaluates the material’s density and uniformity. High pulse velocity indicates good-quality concrete, while lower velocities may suggest voids, cracks, or other defects. The UPV Test is invaluable for detecting internal flaws, estimating the strength of in-situ concrete, and monitoring the progress of curing. It provides engineers with critical data to make informed decisions about maintenance, repairs, and the overall health of concrete structures.

Half Cell Potential Test

The Half Cell Potential Test is a non-destructive method used to assess the likelihood of corrosion in reinforced concrete structures. By measuring the electrical potential between a reference electrode and the reinforcing steel, this test helps identify areas at risk of corrosion. A higher negative potential indicates a higher probability of active corrosion. This test is crucial for the maintenance of concrete structures as it allows early detection of corrosion, enabling timely interventions to prevent significant damage and extend the lifespan of the structure. It provides valuable insights into the durability and performance of reinforced concrete.

Carbonation Depth Test

The Carbonation Depth Test measures the extent of carbonation in concrete, a process where carbon dioxide from the air reacts with calcium hydroxide in the concrete, potentially leading to the corrosion of embedded steel reinforcement. This test involves applying a phenolphthalein solution to a freshly exposed concrete surface, which changes color to indicate the depth of carbonation. Assessing carbonation depth is essential for evaluating the durability of concrete structures and planning maintenance activities. It helps engineers determine the effectiveness of protective measures and the need for remedial actions to prevent structural deterioration and ensure long-term performance.

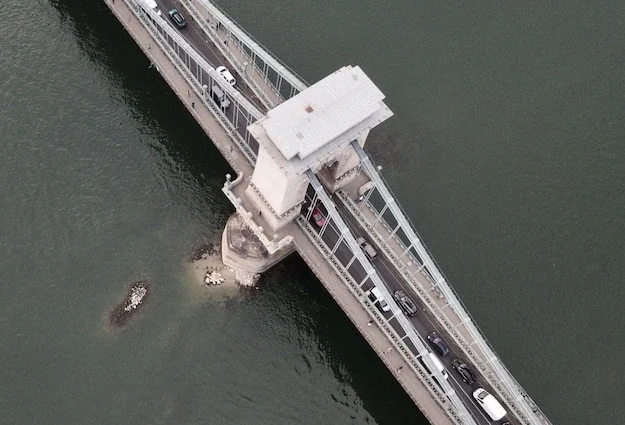

Vibration in Bridge Deck due to moving Truck

Monitoring vibration in bridge decks caused by moving trucks is essential for assessing the dynamic behavior and structural health of bridges. Excessive vibrations can indicate potential issues such as loose components, material fatigue, or inadequate structural design. Using sensors and accelerometers, engineers measure the amplitude and frequency of vibrations to identify problematic areas. This data is crucial for ensuring the safety and longevity of the bridge, allowing for timely maintenance and repair activities. Vibration monitoring helps prevent structural failures, enhances load capacity management, and ensures the comfort and safety of bridge users.

Transient Dynamic Response Test

The Transient Dynamic Response Test evaluates the behavior of bridge structures under transient loads, such as those generated by moving vehicles or environmental forces like wind and earthquakes. This test involves applying a dynamic load to the bridge and measuring its response using accelerometers and strain gauges. The data obtained helps engineers understand the bridge’s dynamic characteristics, identify potential weaknesses, and assess its ability to withstand transient forces. This test is crucial for designing resilient bridges, planning maintenance strategies, and ensuring the structural integrity and safety of the bridge under dynamic loading conditions.

Bridge Load/Proof Load Test

The Bridge Load/Proof Load Test involves applying controlled loads to a bridge to assess its structural performance and load-carrying capacity. This test helps verify the design assumptions and ensure that the bridge can safely support the intended loads. By monitoring the bridge’s response to the applied loads, including deflections and strains, engineers can identify any weaknesses or areas needing reinforcement. The results of this test are essential for ensuring the safety and reliability of the bridge, making it a critical part of bridge evaluation, maintenance planning, and ensuring compliance with safety standards.

Rail Structure Interaction (RSI) analysis.

Rail Structure Interaction (RSI) analysis examines the interaction between railway tracks and the supporting bridge structure. This analysis is crucial for understanding how the dynamic loads from passing trains affect the bridge and vice versa. RSI analysis helps identify potential issues such as excessive deflections, vibrations, and stresses that could compromise the safety and performance of both the rail and bridge. By using advanced modeling and simulation techniques, engineers can optimize the design and maintenance strategies for rail-bridge systems, ensuring safe and efficient operation while extending the lifespan of both infrastructure components.

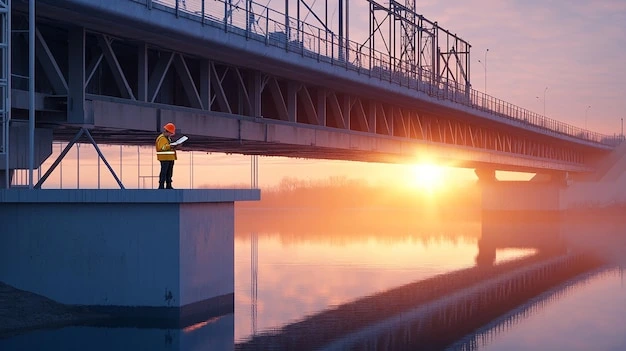

Drone Inspection.

Drone Inspection utilizes unmanned aerial vehicles (UAVs) equipped with high-resolution cameras and sensors to inspect bridges. This method offers a safe, efficient, and cost-effective way to perform visual and thermal inspections, especially in hard-to-reach areas. Drones can quickly capture detailed images and data, enabling engineers to identify cracks, corrosion, and other defects without the need for extensive scaffolding or traffic disruptions. Drone inspections enhance the accuracy and comprehensiveness of bridge assessments, providing valuable insights for maintenance planning and ensuring the safety and longevity of bridge structures.

Complete Temperature monitoring.

Complete Temperature monitoring in bridge structures involves using sensors to continuously track temperature variations. This monitoring is essential because temperature changes can cause expansion and contraction in materials, potentially leading to structural stress and damage over time. By measuring temperatures at multiple points, engineers can assess the impact of thermal fluctuations on the bridge’s integrity. The data collected helps in identifying areas susceptible to thermal stress, planning maintenance activities, and ensuring the bridge’s long-term durability and safety. Temperature monitoring is a critical component of comprehensive structural health monitoring systems.

Static / Dynamic Load testing.

Static or Testing assesses the performance of bridge structures under various loading conditions. Static load tests involve applying steady loads to evaluate the bridge’s load-carrying capacity and deflection behavior. Dynamic load tests, on the other hand, simulate real-life conditions by applying time-varying loads, such as those from moving vehicles or environmental forces. These tests provide valuable data on the bridge’s strength, stiffness, and dynamic response, helping engineers verify design assumptions, detect structural deficiencies, and plan necessary reinforcements. Load testing ensures the bridge can safely withstand its intended loads, enhancing overall safety and reliability.

Rehabilitation and retrofitting designs (Bridges, Buildings and special structures)

Rehabilitation and Retrofitting Designs focus on enhancing the performance and extending the lifespan of existing bridges, buildings, and special structures. These designs address issues like material deterioration, increased load demands, and compliance with updated safety standards. Rehabilitation involves repairing and strengthening damaged or weakened components, while retrofitting includes adding new elements to improve structural performance. Engineers use advanced materials and techniques to ensure that the structures can meet current and future demands. Effective rehabilitation and retrofitting designs enhance safety, functionality, and resilience, ensuring that these structures continue to serve their intended purposes efficiently.

Vibration Monitoring

Vibration Monitoring in bridge structures involves the use of sensors to measure the amplitude, frequency, and duration of vibrations caused by traffic, wind, and other environmental factors. This data helps engineers understand the bridge’s dynamic behavior and identify any unusual patterns that may indicate structural issues, such as cracks, loose components, or foundation problems. Continuous vibration monitoring is crucial for the early detection of potential faults, enabling timely maintenance and repair. It enhances the safety and longevity of bridges by ensuring that they can withstand dynamic loads without experiencing excessive stress or damage.

Deflection Monitoring

Deflection Monitoring tracks the vertical displacement of bridge components under load. This monitoring is essential for assessing the structural performance and ensuring that the bridge maintains its designed shape and load-carrying capacity. Excessive deflection can indicate problems such as material fatigue, insufficient stiffness, or structural damage. By using sensors to measure deflection in real time, engineers can detect anomalies early, plan appropriate maintenance, and prevent potential failures. Deflection monitoring provides critical data for evaluating the bridge’s health, ensuring its safety, and optimizing its performance under various loading conditions.

Tilt Monitoring

Tilt Monitoring measures the angular displacement or inclination of bridge components, such as piers and abutments. This monitoring is crucial for detecting shifts or movements that could compromise the bridge’s stability and safety. Tilt sensors provide real-time data on any changes in inclination, enabling engineers to identify potential issues like foundation settlement, lateral movements, or structural deformations. Early detection of tilt can prevent significant structural problems and ensure the bridge’s integrity. Tilt monitoring is an essential part of comprehensive structural health monitoring, contributing to the overall safety and longevity of the bridge.

Strain Monitoring

Strain Monitoring involves measuring the deformation of bridge materials under load. Strain gauges attached to critical structural components provide real-time data on the extent of strain, helping engineers assess the bridge’s load-bearing capacity and identify areas of stress concentration. Continuous strain monitoring is vital for detecting early signs of material fatigue, cracking, or other structural issues. By understanding the strain behavior, engineers can make informed decisions about maintenance and repairs, ensuring the bridge remains safe and functional. Strain monitoring enhances the accuracy of structural assessments and contributes to the long-term health of the bridge.

Stress Monitoring

Stress Monitoring measures the internal forces within bridge materials caused by external loads. Using sensors like strain gauges, engineers can determine the stress levels in various bridge components, such as beams, columns, and cables. Monitoring stress is crucial for identifying areas at risk of overloading, material fatigue, or failure. Real-time stress data helps in assessing the bridge’s structural performance, optimizing load distribution, and planning maintenance activities. By ensuring that stress levels remain within safe limits, engineers can enhance the bridge’s safety, durability, and resilience to dynamic and static loads.

Crack-Growth Monitoring

Crack-Growth Monitoring tracks the initiation and propagation of cracks in bridge structures. Using advanced sensors and imaging techniques, engineers can detect and measure the size and growth rate of cracks over time. This monitoring is essential for assessing the structural integrity and preventing catastrophic failures. Early detection of crack growth allows for timely intervention and repair, ensuring the bridge’s safety and longevity. Crack-growth monitoring provides valuable insights into the material behavior and performance under various loading conditions, contributing to the overall health and maintenance strategy for the bridge.

Temperature Monitoring

Temperature monitoring involves the continuous measurement of temperature variations in bridge components. Using sensors placed at strategic locations, engineers can track thermal changes that affect the bridge’s materials. Temperature fluctuations can cause expansion and contraction, leading to stress and potential damage over time. By monitoring temperatures, engineers can identify areas at risk, plan maintenance activities, and ensure the bridge’s structural integrity. Temperature monitoring is a crucial aspect of comprehensive structural health monitoring, helping to maintain the safety, durability, and performance of bridge structures under varying environmental conditions.

Humidity Monitoring

Humidity Monitoring tracks the moisture levels in and around bridge structures. High humidity can accelerate the corrosion of metal components and degrade concrete, compromising the bridge’s integrity. Using humidity sensors, engineers can monitor moisture levels in real time, identifying areas susceptible to corrosion and other moisture-related issues. This data is critical for planning maintenance and implementing protective measures to extend the bridge’s lifespan. Humidity monitoring enhances the understanding of environmental impacts on the bridge, ensuring that it remains safe and durable under different climatic conditions.

IoT-Based SHM System

An IoT-Based Structural Health Monitoring (SHM) System integrates advanced sensors, data analytics, and wireless communication technologies to provide real-time monitoring of bridge structures. IoT-enabled sensors continuously collect data on various parameters like stress, strain, vibration, temperature, and humidity. This data is transmitted to a central platform, where it is analyzed to detect anomalies, predict potential failures, and optimize maintenance schedules. IoT-based SHM systems enhance the efficiency and accuracy of structural assessments, enabling proactive maintenance and improving the safety and reliability of bridges. These systems represent a significant advancement in bridge monitoring and management.

Amenities

Anemometers

3D Accelerometers

Temperature Sensors